Synthy (formerly 'music box') - May

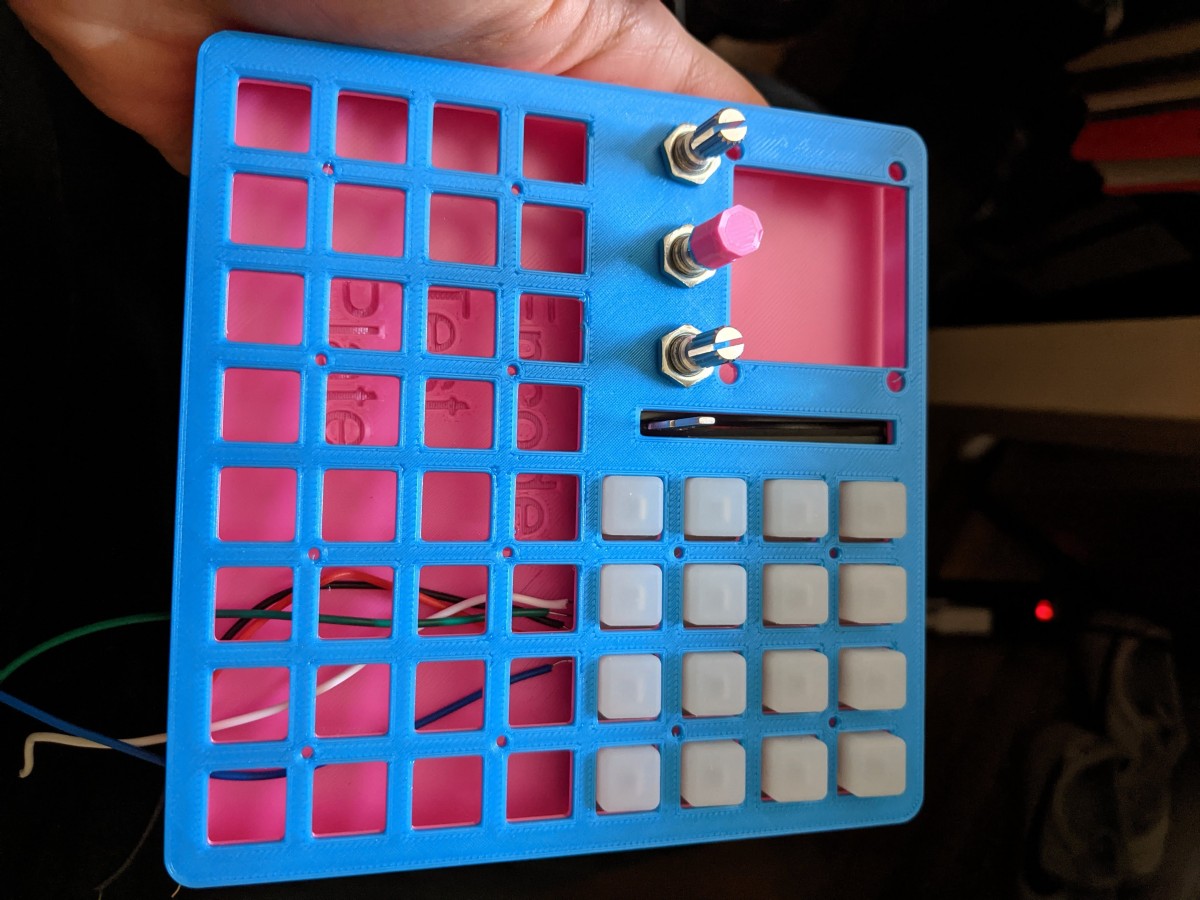

24 May 2021Time for the May monthly update of the Aarav Syngth Experience! I'm writing this one, technically, right as I wrap up June and enter July (that's when I set up this site, so I'm backlogging a couple months). So what did the idea look like back in May of 2021? Well, in material reality, the idea looked something like this a couple days before May started:

The title of today's blog post, Synthy, has been the working title for this project for a while. I've also called it The Aarav Syngth Experience and ASE v0 in the same vein.

Anyway, at this point there are no brains inside that baby, it's just the outer shell of what a music box could possibly be. May was also about the time that I figured I'd get an OP-1, which you can see side by side next to this iteration of Synthy and an Arturia MiniLab.

Full disclosure on my music setup, for the few of y'all who may be curious, I also have a Roland F-90 and three guitars (a partially broken Yamaha FG800 which I fashioned into a kalimbatar, an Orangewood Rey Mahogany I picked up on sale after I first broke the Yamaha, and a noname ebay stratocaster I got to see what all this "electric guitar" hubbub is about). It's good gear that serves me well, despite its relative affordability. I've accrued it over the course of almost 20 years (thanks, in huge part, to my parents and favorable circumstances) and I hope to keep it from growing too much more than it has already. I don't think what gear I own is all too important, but it does give some insight into what sorts of instruments I've grown up playing and how my musical perspective has developed.

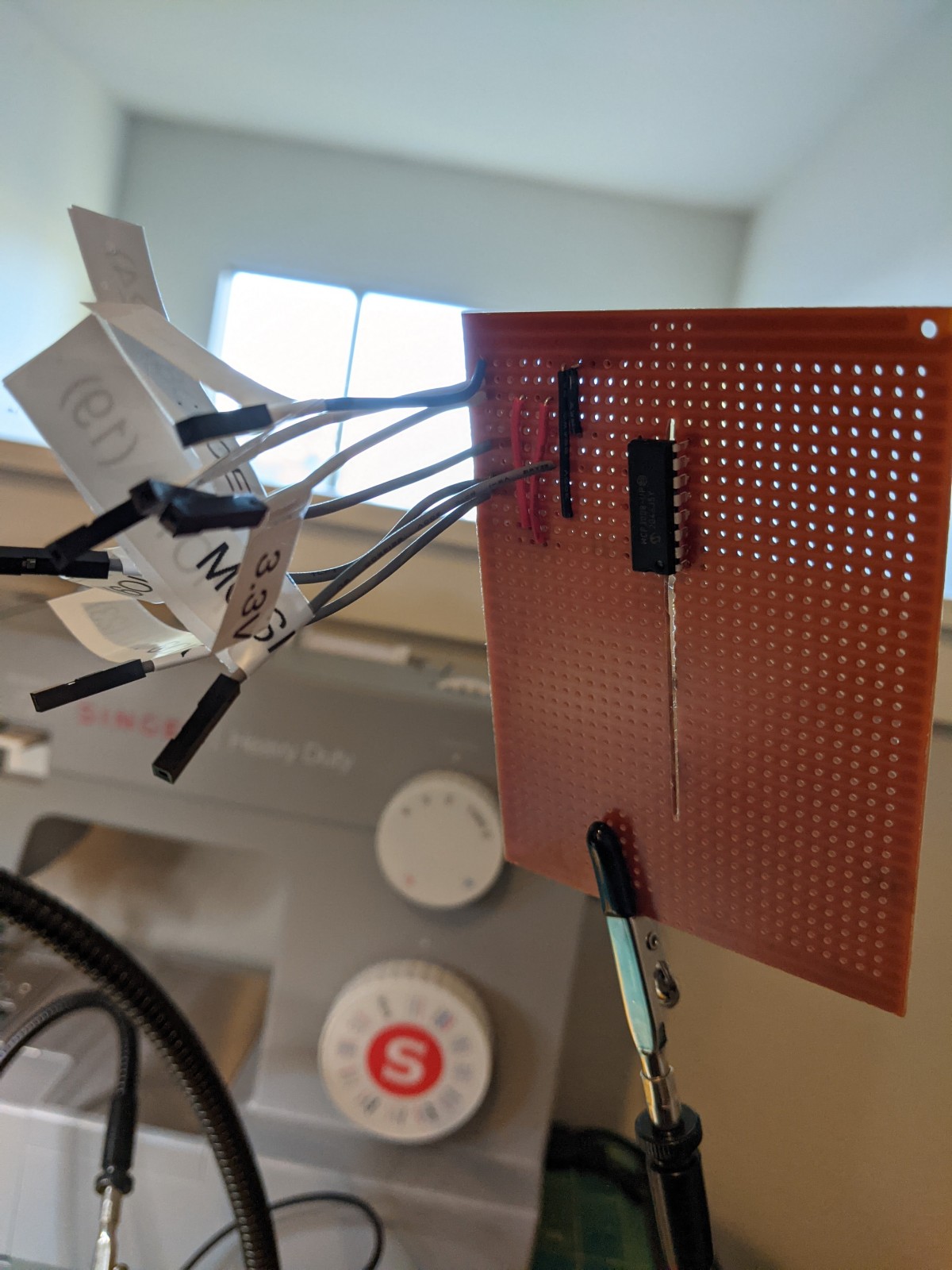

Getting into Synthy progress for this month, we can start by looking at the baby steps I started with while building out the first motherboard (I refer to the main pcb of Synthy as a "mobo" or "motherboard" but I'm not sure if those terms are truly applicable if we're using a raspi or other single-board computer in conjunction with the main pcb. lmk if you think I should call it something else)

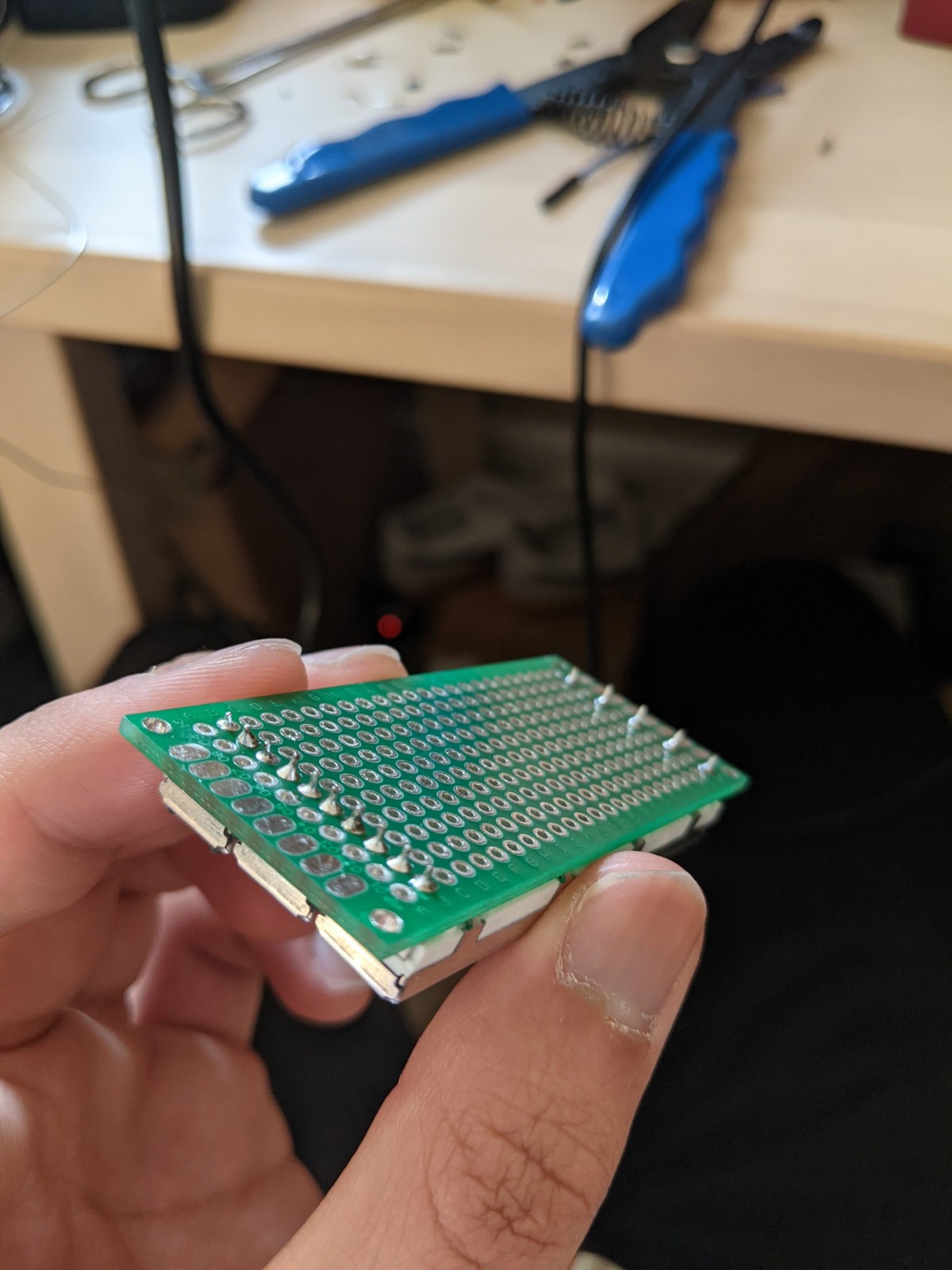

My soldering skills continue to improve with every iteration, and the amount of times I've had to solder these button PCBs has in and of itself contributed to that improvement significantly

On the other hand, I've only soldered the sliders together one time. Like a dream come true honestly

but my buddy Mischa did absolutely destroy at least one slider in a goop of hot solder, no parts have remained completely unharmed during this production process.

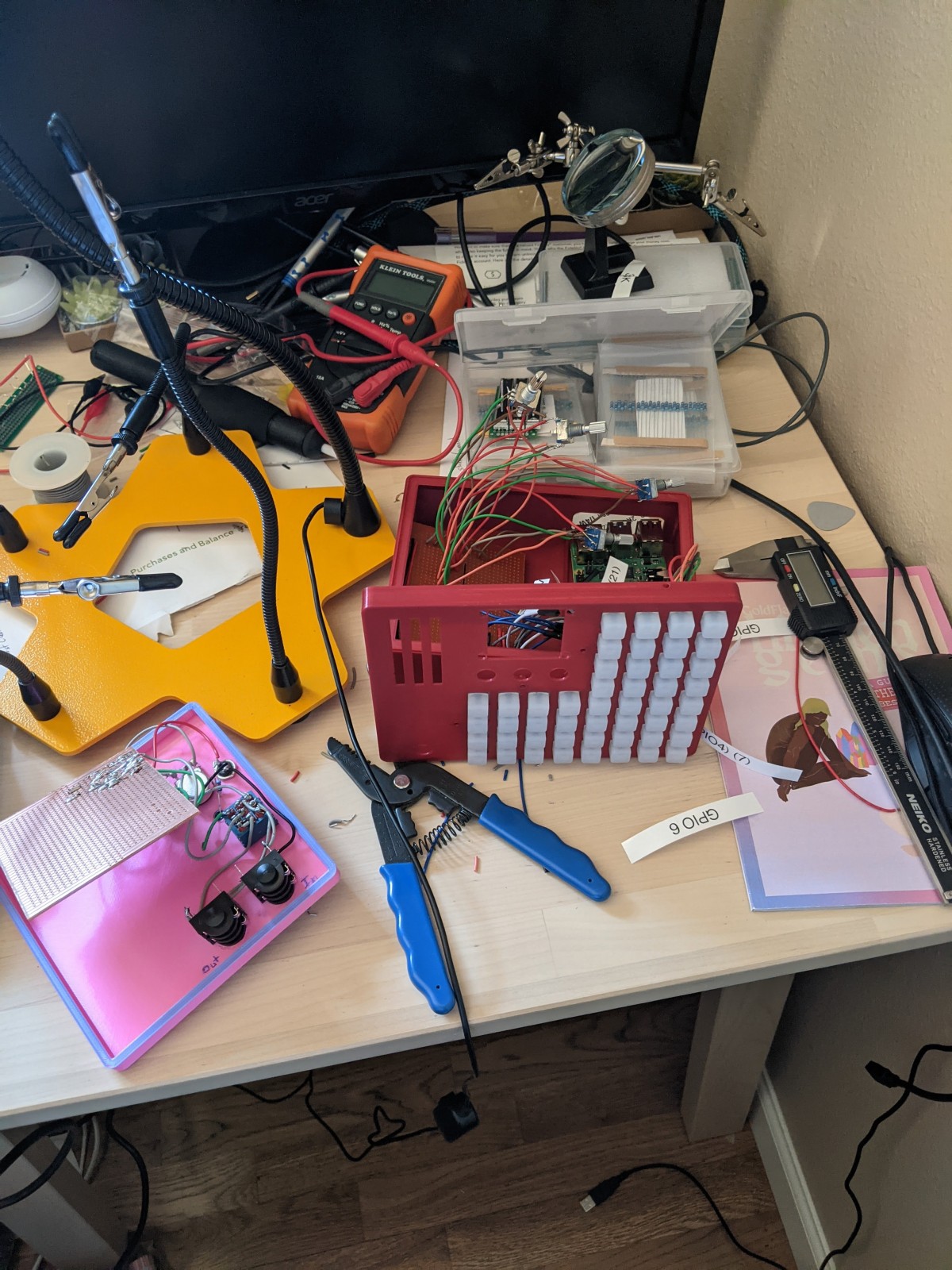

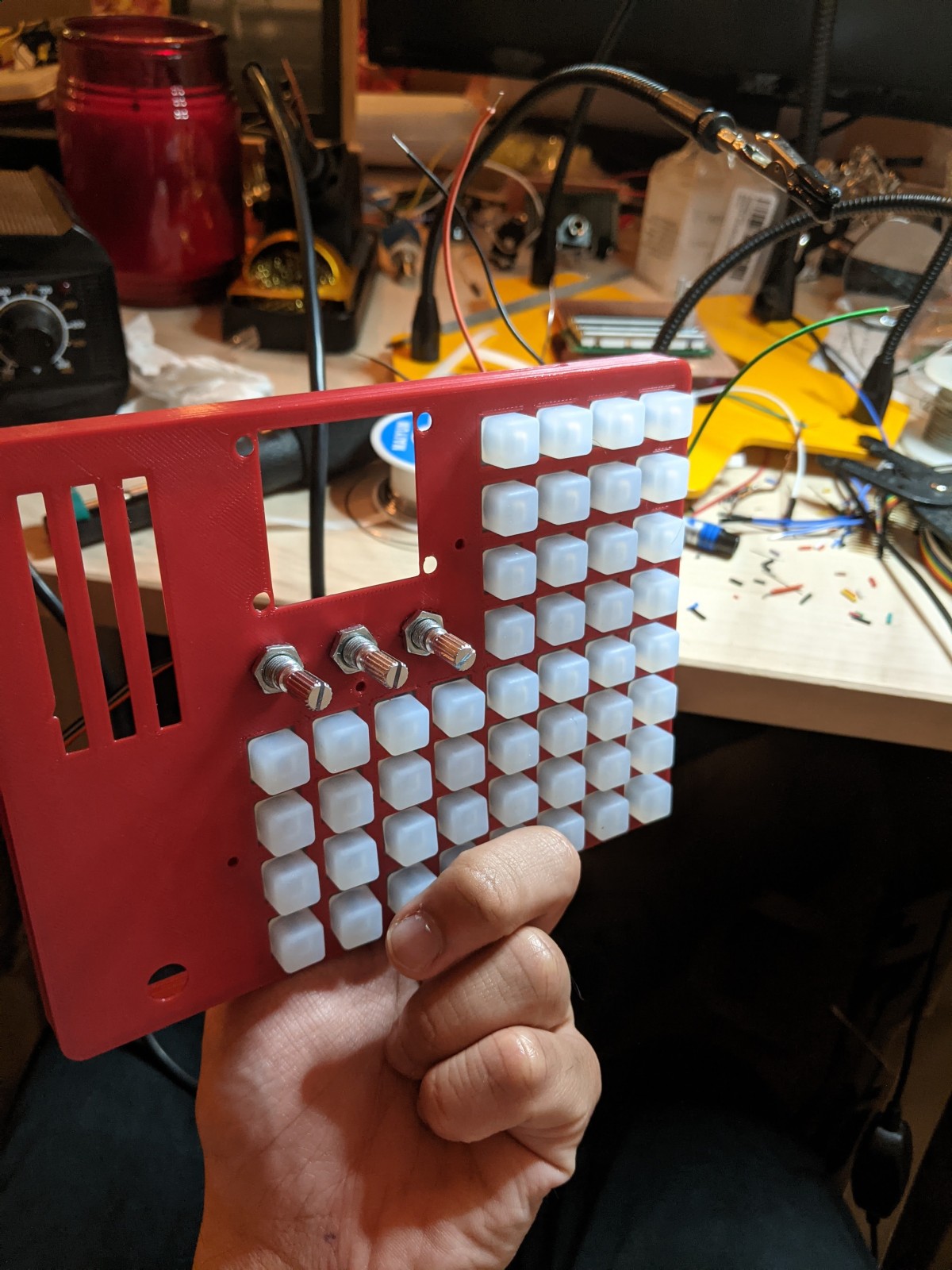

After completing a bit of the motherboard, we got the pi, first gen mobo, faceplate, and encoders all fitting inside the box properly

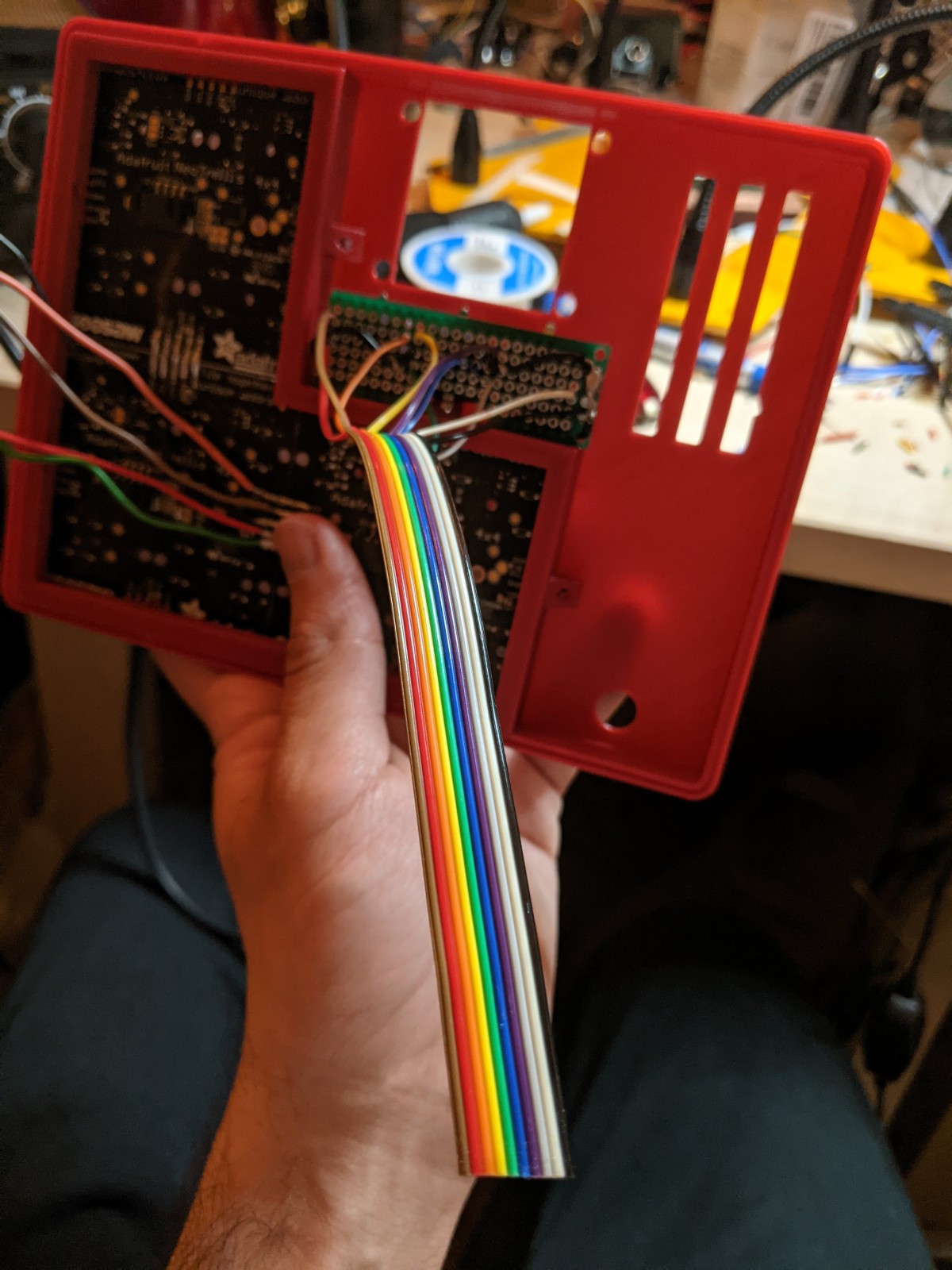

Although that setup works, the testing cycle time was atrocious because of how many plugs everything has. Plugging in/out 10 wires on the pi, 5 wires on the buttons, 10 wires for the encoders, etc, etc. That meant that a major priority for prototyping became cycle efficiency, which led me to ribbon cable! That way, every component (or group of components, ideally) only requires one connection point to the mobo. Here's what the encoders and buttons look like partially ribbonified

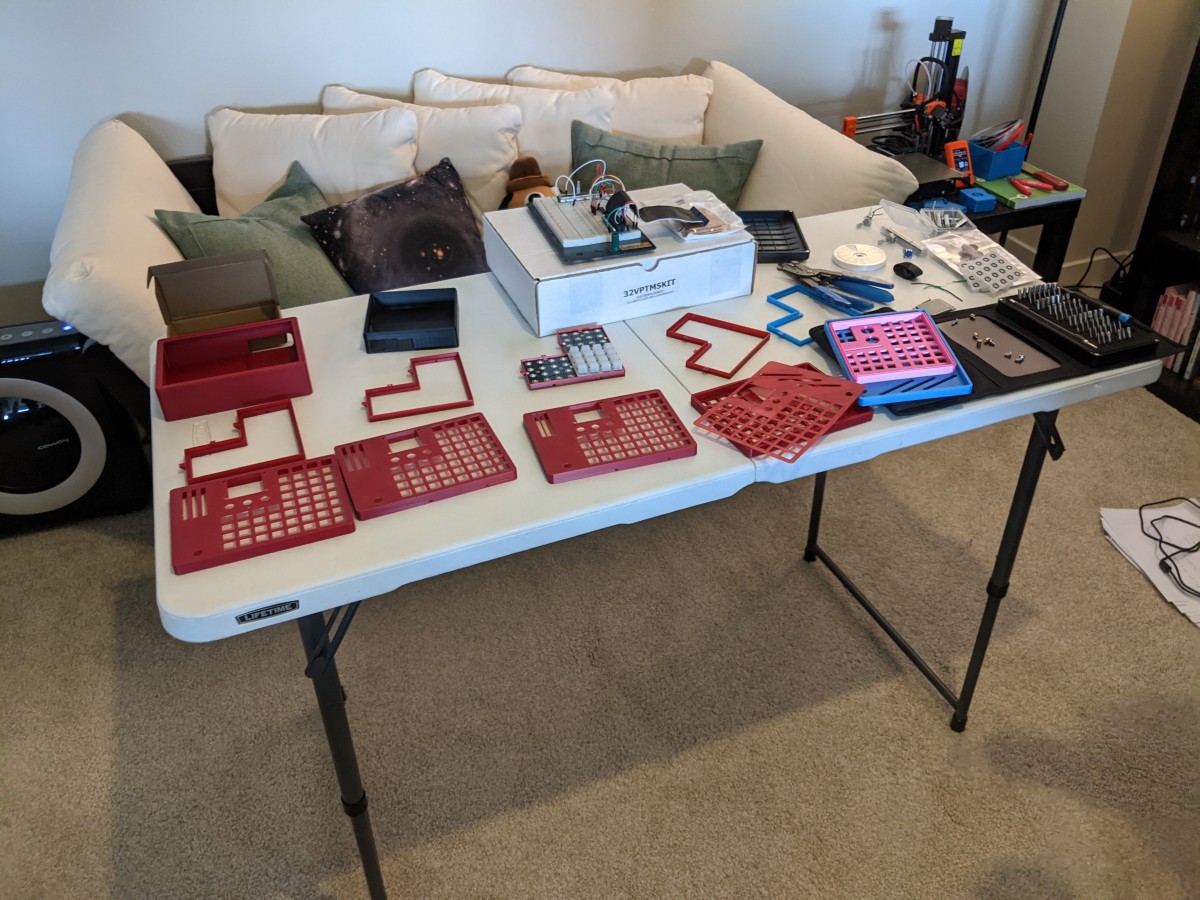

I've saved the next image for last because it's one of the coolest moments I've experienced working on this project. Presumably that's because none of this work was my own, this is a shot of Mischa's apartment with a bunch of (just slightly incorrect) Synthy prints.

I didn't expect to see about 10 versions of my initial design printed, tested, and iterated on. Walking into that room was a special feeling, and it reminded me of a few things that I'll end with:

- seeing others take one of your ideas and run with it is cool. I want to be able to see people take the instruments I build and run with them, either musically (by playing em) or otherwise (by modding, DIYing their own, creating their own variants of some of the ideas, etc).

- modern DIY technology is incredibly powerful. Despite the fact that I'm fairly limited by resources (compared to big tech companies, if not to individuals), I'm able to take relative control of a complete end-to-end product and make it a reality. I can procure most necessary fabrication/assembly materials myself and outsource specialized production (eg. PCB printing) at relatively affordable cost.

- I'm in a unique situation right now, being able to leverage my experience, passion, and time towards a project I care about. Few people can quit their jobs to pursue passion projects. I'm lucky to be able to sacrifice income and stability for a temporary dream; lucky to have the safety nets necessary to make such a drastic life change. For however long I do get to pursue this, and however far the project gets, I don't intend on taking it for granted. Thanks a bunch (to Mischa especially, for the tireless work and dedication. but also to you, dear reader, for following along for the ride) - this project will, soon enough, come to an end. Here's to hoping that the impact lasts just a bit longer than I do.